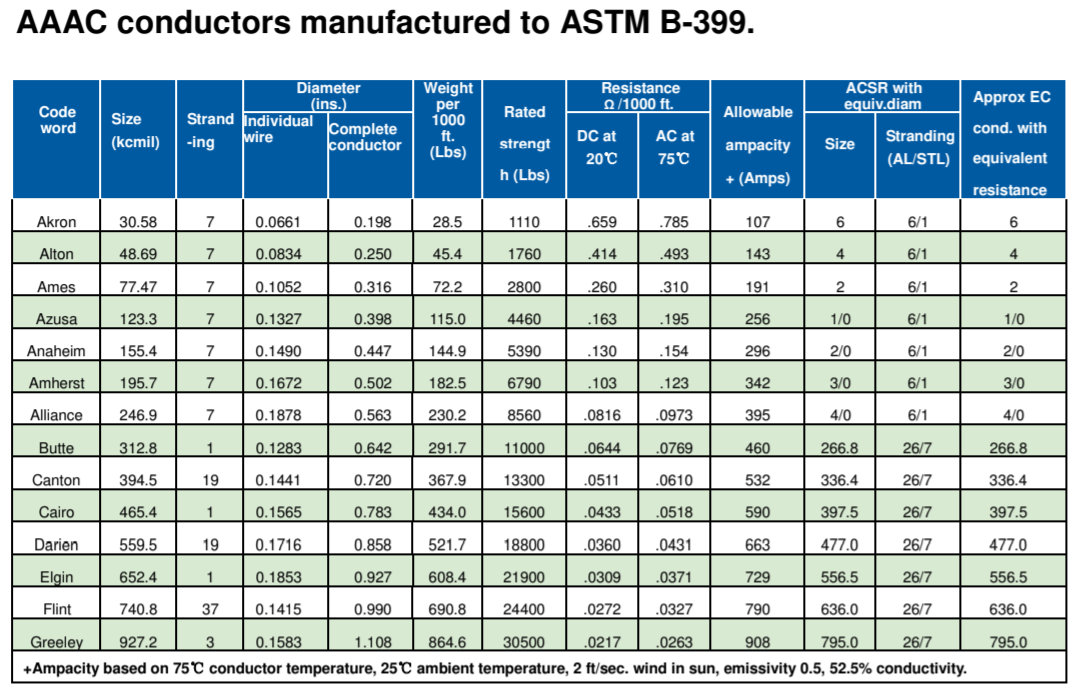

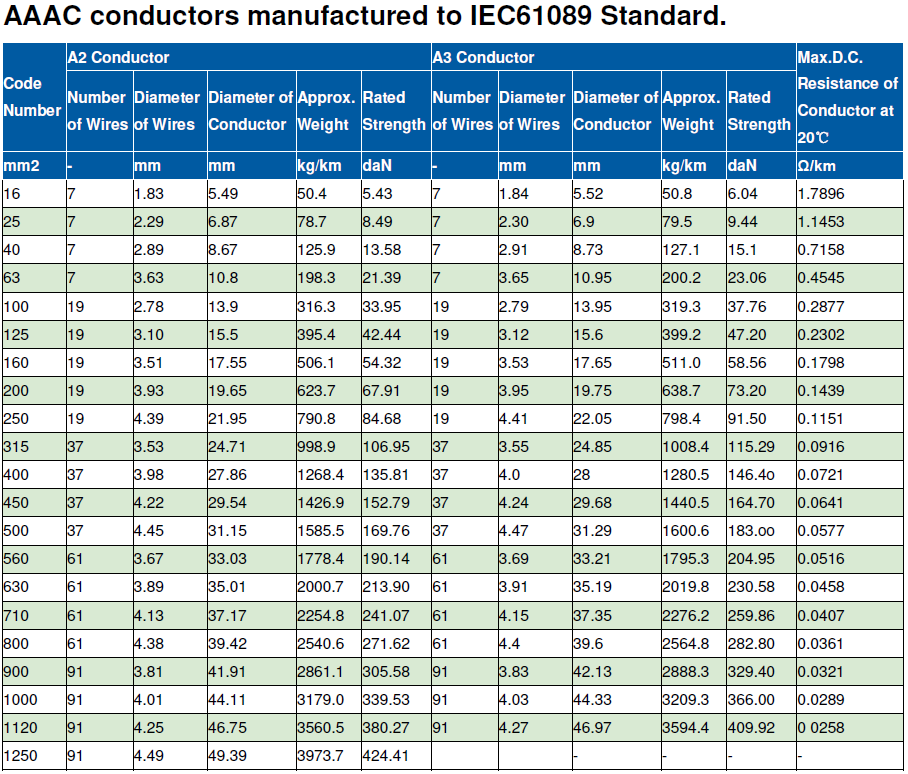

All Aluminum Alloy Conductor AAAC cable, aluminium alloy conductor, has not insulation and sheath, meet to ASTM B-399, ASTM B-231, IEC 61089, GB/T 1179, BS EN 50183.

Brand:

ElectricaltechItem NO.:

XTD--Aerial-04Order(MOQ):

10000 metersPayment:

T/T 30% the deposit, the balance will be paidMarket Price:

$/M 0.4Price:

$0.35/0.38 per meterProduct Origin:

Hubei, China.Color:

Primary colorsShipping Port:

Wuhan, Shanghai, Shenzhen, Guangzhou, or other Chinese port.Lead Time:

Within 10-20 working days as soon as weWeight:

95 KG/KMAll Aluminum Alloy Conductor AAAC cable

PRODUCTS KEYWORDS

AAAC cable, AAAC bare conductor, all aluminum alloy conductor bare cable, aluminum alloy aerial cable, all aluminum alloy cable.

PRODUCTION APPLICATION

Electricaltech brand All Aluminum Alloy Conductor AAAC cable, concentric lay stranded Aluminium Alloy Conductors (AAAC) are made out of high strength Aluminium-Magnesium-Silicon Alloy. Electricaltech Cable manufactures and supplies AAAC with different variants of electrical grade alloy type 6101 and 6201, one or more strands of hard drawn 1350 aluminium alloy. It is similar in construction and appearance to the AAC all-aluminum conductor.

PRODUCTION FEATURES

1. High strength to weight ratio.

2. Better sag characteristics.

3. Improved electrical properties.

4. Excellent resistance to corrosion.

5. Higher operating efficiency of the line.

All Aluminum Alloy Conductors have a number of advantages over the use of the ACSR or all-aluminum conductors.

1. Lower power losses than for equivalent single-aluminum-layer ACSR conductors.(The inductive effect of the steel core in the ACSR is eliminated.)

2. Simpler fitting than those required for ACSR.

3. Excellent corrosion resistance in environments conductive to galvanic corrosion in ACSR.

4. Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

5. Outside diameters are the same for standard ACSR conductors, permitting interchangeability of fitting.

6. Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

Note:

• Resistance is calculated using ASTM standard increments of stranding and metal conductivity of 52% IACS, AC resistance at 60Hz.

• Current ratings are based on 80ºC conductor temperature, 50ºC ambient, 0.6 meter/second wind, 1200 watts/sq. meter solar heat radiation, 0.5 coefficients of emissivity and absorption.

PRODUCTS STRUCTURE

---Conductor Material

Aluminium alloy conductor.

---Insulation Material

Non-insulation

---Sheath Material

Non-sheath

---Core Number

Single core, 1C.

---Working Temperature

-0℃~+70℃.

---Installation Temperature

0℃ ~+40℃

---Minimum Bending Radius

20 x Overall Diameter.

---Production Standard

GB/T 12527-2008, GB/T 14049-2008, IEC 61089, ASTM B-231, ASTM B-399, BS EN 50183.

---Product Packing

Wooden drum.

---Product MOQ

10000 meters.

---Production Delivery

Within 10-20 working days as soon as we received the deposit.

PRODUCTS STRUCTURE

REMARK

---The information contained within this datasheet is for guidance only and is subject to change without notice or liability. All the information is provided in good faith and is believed to be correct at the time of publication.

---When selecting cable accessories, please note that actual cable dimensions may vary due to manufacturing tolerances.

---The OEM or OBM service will be accepted, but the customer should be provided the authorization letter to us in advance, and the authorization letter must be true and valid.

---Electricaltech Cable: Embrace New Times, Co-create Xintiandi; Focus on Quality, Foremost Service.

---Electricaltech Cable: Good Material, Reasonable Weight, Enough Length, well-known brand wins your trust.

MAIN ADVANTAGE

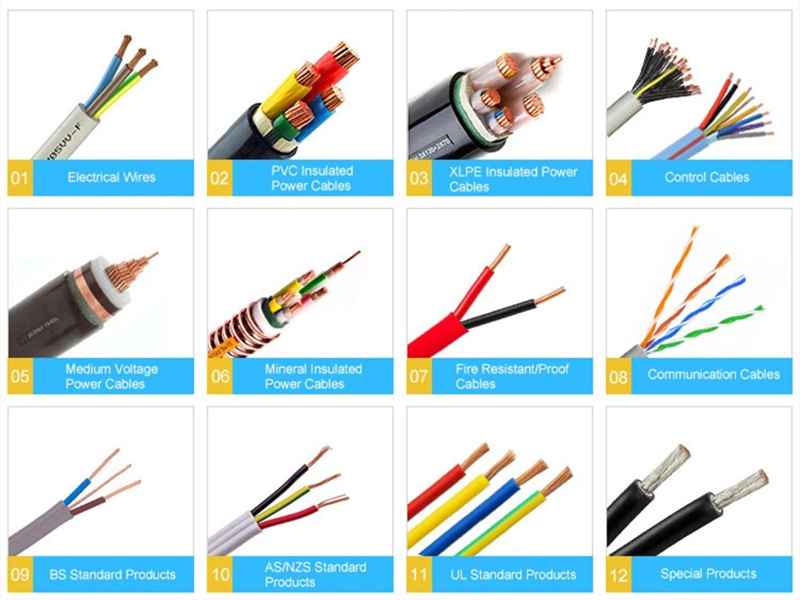

HOT-SELLING PRODUCTS

RAW MATERIAL

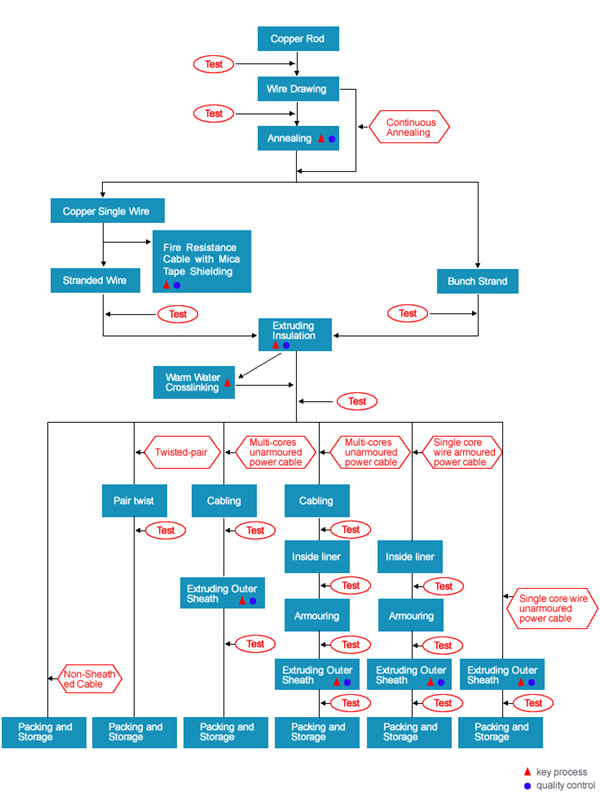

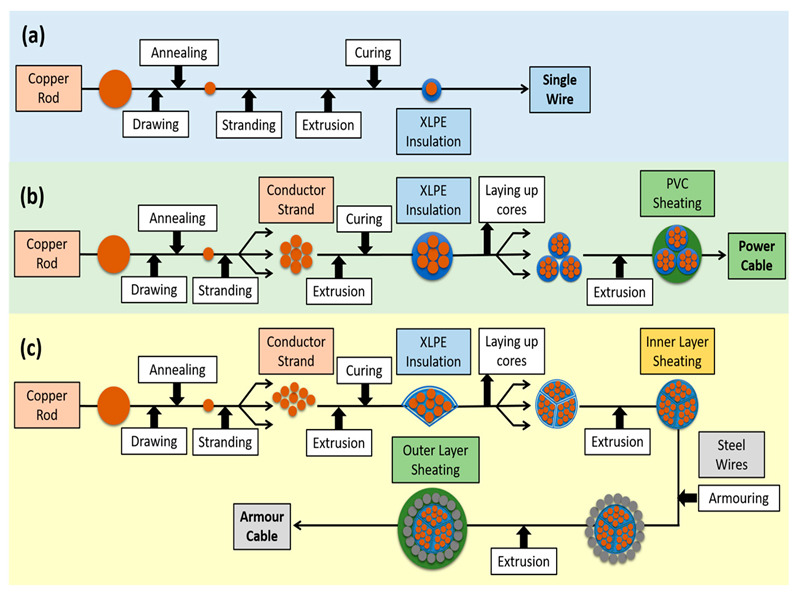

PRODUCTION PROCESS

INSPECTION PROCESS